Do you require a fully assembled conveyor belt? BTE has one of the most extensive belt fabrication workshops in Europe.

Your belt tailor-made

Over the years, we have developed an extensive fleet of machines, with which we can quickly and correctly carry out even the most complicated fabrication processes. By always staying on top of the latest developments in plastics technology and by investing in new techniques and methods of working, you can rest assured you’ll receive bespoke fabrication work of the highest quality.

We are happy to present some special fabrication activities to you:

In 2017 Bandtransport Europe invested in a new digital cutting system. This fully computer-controlled cutting plotter cuts out the most complicated designs quickly and accurately. Perforations no longer need to be punched by hand, but can be placed accurately in any size and spacing. BTE can easily and quickly process your order, also when large volumes or special designs are concerned.

Bandtransport Europe has chosen a Zünd digital cutting system. The Zünd G3 XL3200 digital cutter offers us the options and the high processing quality corresponding with our aim to supply you with only the best products. With a processing surface of 2270 x 3200 mm even larger designs can be cut out with precision. Not only does this give us the opportunity to supply more complex products, you can also count on a continuation of our high quality.

Are you looking for a special conveyor belt? Sometimes existing material will only partially meet your requirements and the development of a completely new type of conveyor belt is not practicable. At BTE we offer the possibility of applying additional covers in accordance with your specifications. This technique is for instance utilised for the coating of cable pulling belts: An additional coating with the required hardness and friction is applied to existing material that has been made endless in order to create a strong, seamless belt with a long service life. We can also apply extra coatings to existing belt materials (endlessed if required) for a variety of other applications. Please let us know your requirements. We will be happy to advise you.

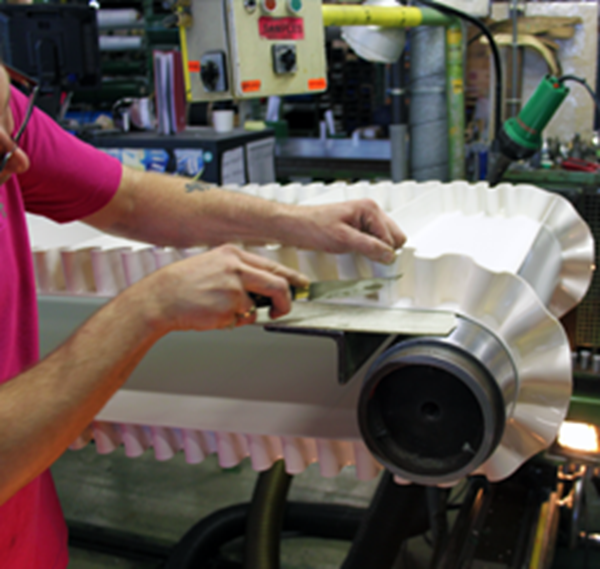

The bespoke profiling of conveyor belt material is also a special, quite unique process with which we have been able to help many of our customers. Would you like to have existing material embossed with a profile? No problem. BTE offers a comprehensive range of current profiles that can be embossed on existing, flat belts. In addition to the profiling of a complete belt, we furthermore offer the unique possibility of only profiling a small section of belt material. In this manner, you can combine the purchasing of full slabs of material with the purchasing of smaller quantities of one or more profiled belts. Please feel free to contact us for additional information or to receive a quote.

The following fabrication activities are carried out according to your specifications:

Feel free to contact us. We'll be happy to assist.