Bandtransport Europe has a large range of standard and customised conveyor belts. Depending on your wishes and industry, we will develop a conveyor belt that fits in perfectly with your production process. But how do you find the right conveyor belt for your application?

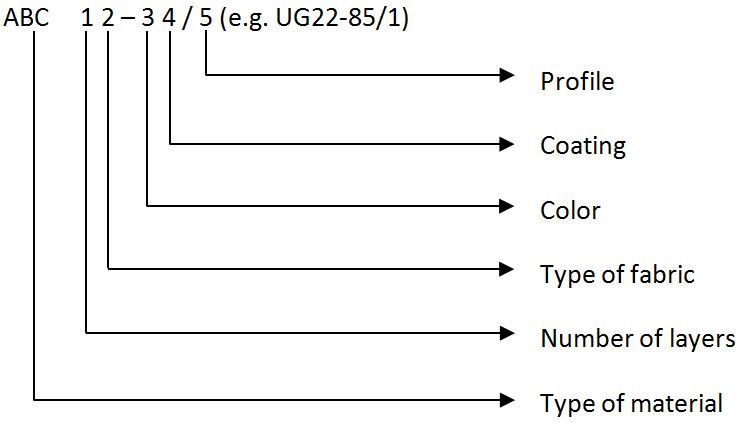

Our conveyor belts are coded in accordance with a dedicated structure. This makes it very easy for you to find the right conveyor belt.

Choosing a conveyor belt starts with selecting the right material. As a standard, Bandtransport Europe’s conveyor belts are available in three different materials:

In addition to these standard materials, BTE also offers three other materials:

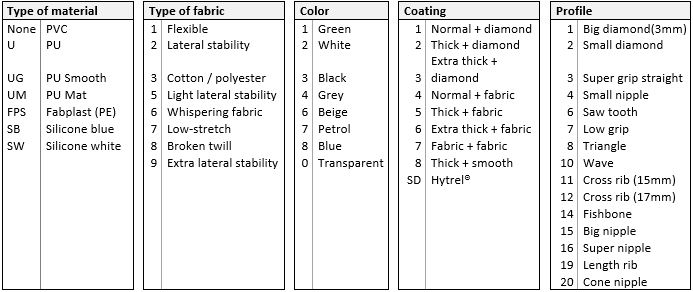

These materials have different coding, that provides more information: Wire mesh is indicated with an µm value (500µm, 1000µm etc.), indicating the mesh width in micro metres. Belts with a hard Hytrel® coating are indicated with the letters SD behind the coding (e.g. 21-13SD). For silicone conveyor belts, we use the code SB or SW, SB indicating silicone blue and SW silicone white. A final code of a silicone conveyor belt could be SB22-07UA, for instance.

PVC conveyor belts form the biggest group of belts in Bandtransport Europe’s product range. PVC, polyvinyl chloride in full, is the basic material for PVC conveyor belts and is suitable for almost any application thanks to its versatility. You can choose from different types of hardness, colour and thickness, in combination with various types of fabrics.

Benefits of PVC conveyor belts

PU (polyurethane) is harder than PVC. This makes PU conveyor belts very hard-wearing. They are also highly resistant against oil and grease/fat. This type of plastic is flexible and can be used in very thin layers, making it possible to run the belt over very small drums and knife transitions.

Benefits of a PU conveyor belt

PE (polyethylene) conveyor belts are hard-wearing and have excellent release properties. Also, PE is characterised by its high chemical resistance and no toxic substances are released during combustion. These types of belts are often used in the tobacco industry.

Benefits of a PE conveyor belt

Wire mesh belts are made of polyester wire mesh and fitted with PE (polyethylene) edge reinforcement. They are often used for washing, drying, sieving and drainage applications, which means they have to be highly water-permeable.

Benefits of a wire mesh belt

Conveyor belts coated with Hytrel® are highly durable, as they are made of a strong, hard-wearing plastic. This means Hytrel® conveyor belts have a long lifespan and they can be used in industries that put heavy strains on the conveyor belt.

Benefits of a Hytrel® conveyor belt

Silicone conveyor belts are mainly used in the food industry, especially where products need to be ‘released’. One side of the conveyor belt can be fitted with an edge, closing it. The belt can then release products (such as biscuits) on the other side. Thanks to the texture of the material, silicone has both excellent release properties and grip during horizontal movement. The product stays in place when moving and does not stick to the belt at the end of the process. As a standard, BTE supplies its silicone belts with a PU centre layer. This gives these belts additionally strong structural and anti-static properties.

Benefits of a silicone conveyor belt

On our specially developed profiling machine we can emboss conveyor belt material with a profile of your choice. We offer 20 different profiles to give your conveyor belt the unique properties you need.

You can choose various types of coating for a conveyor belt. You can choose from two coatings for the top: fabric and plastic of various degrees of thickness:

| Material | PVC | PU | ||

| Normal | 0,7mm thick | 0,2mm/0,3mm thick | ||

| thick | 1,0mm / 1,5mm thick | 0,7mm thick | ||

| Extra thick | 2mm thick | 1mm thick | ||

| Fabric |

In addition to various choices for the top coating, BTE offers three choices for the undercoating:

Example code 22-16, coating no. 6 is extra thick + fabric

This belt has an extra thick plastic 2-mm top and a fabric bottom.

Bandtransport Europe has a large range of standard and customised conveyor belts. Depending on your wishes and industry, we will develop a conveyor belt that fits in perfectly with your production process. These (customised) conveyor belts are also available in small batches. More information? Please contact us.