Are you looking for a conveyor belt to transport products that require a delicate touch, or do you need to transport products in a wet environment (where a good discharge of liquid is required)? A conveyor belt with so-called finger cleats, or finger belts, is the ultimate solution.

Among other things, finger belts make it easier for you to position products. The product is kept in place without it rolling, so it will not get damaged or become useless. As such, a conveyor belt with finger cleat is a conveyor belt for the transport of delicate products. In a wet environment, a finger belt ensures any excess liquid is discharged properly.

The finger cleat thanks its name to one of the shapes in which the cleat is available. However, finger cleats come in all shapes, sizes and colours. An overview of shapes and sizes available is given below.

Bandtransport Europe carries eight different types in its range, five PVC types and three TPU types. Most of our product range is also available separately (from 100 items) and can of course also be fitted on a conveyor belt by BTE.

The fingers are available in two different materials. You can opt for the well-known PVC (polyvinyl chloride), but you can also choose TPU (thermoplastic polyurethane). TPU is a plastic with a higher hardness and the advantage is that the finger can be fitted to conveyor belts with both a PVC and PU top layer.

BTE has paid a lot of attention to the chemical composition of the fingers, so they are durable and virtually all of them comply with the guidelines for food contact.

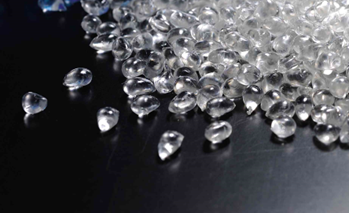

Our fingers are manufactured during a so-called injection mould process. Injection moulding is a design technology for plastics. During injection moulding, plastic, supplied as granulate or powder, is melted into a viscous mass and injected into a mould under high pressure. The cavity of the mould has the shape of the desired finger. The plastic sets when it cools down, forming the desired finger. Injection moulding is one of the most common design technologies of plastic components.

The fingers on our conveyor belts are fitted onto the belts by means of a special, efficient and high-quality assembly technique. Bandtransport Europe positions the fingers onto the conveyor belt individually (see row 1). This means it does not use a so-called strip (see row 2). In the case of a strip, the fingers are already attached to the strip and are then fixed to the conveyor belt.

Apart from saving time and money with this special technique, the fingers are secured stronger and more appealingly compared to conventional assembly by means of a strip. The main advantage of this assembly method is that the finger belt has no upright edges, strongly reducing the risk of contamination. The discharge of liquid, and as such hygiene, is also considerably improved.

We do for that matter offer the option of affixing the fingers to a strip first and then to the conveyor belt.

Among other things, conveyor belts with finger cleats are used for the following applications:

If you need more information about finger belts or fixing fingers on a conveyor belt, please contact Bandtransport Europe on +31 (0) 251 319 119 or use our contact form